Corode

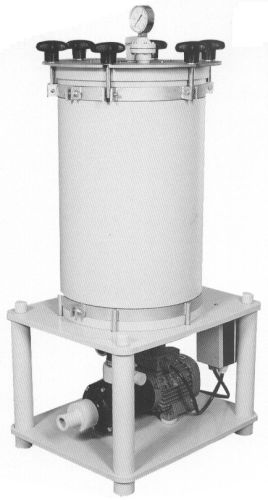

Filter units - Series CF15M

with magnetic drive pump - 15,000 l/h

|

- Choice

of plates, filter paper (P), filter cloth (B) or filter

cartridges

(C) -interchangeable-

- Large

filter surface areas provide long operation time between

media change

- No

metal parts in contact with the solution

- Units

with magnetic drive type pump

- Extensive

use of polypropylene provides excellent chemical resistance

and mechanical strength (max 75C)

- Standard

units include air release/drain valve, pressure gauge,

suction strainer and 2.20m electric cable

- Dry

run protector, hand pump, pre-coat, hoses and transport

wheels

are optional

- Filter

chamber

has a fixed bottom (seal-less)

- Outside

metal parts: SS316

|

|

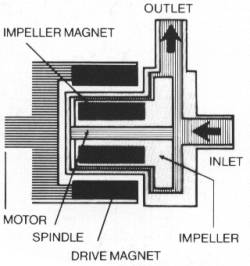

The

Magnetic Drive - How it works

- The electric motor

provides the electromotive force that drives the system

- The drive magnet

is attached to the electric motor and transfers the motor-HP to the

pump system

- The impeller magnet

housing creates a stationary wall between drive magnet and magnetic

impeller, eliminating the trouble-some seal

- The magnetic impeller

spins on the stationary ceramic spindle and is lubricated by the liquid

|

|

|

Type

|

Filter

medium

|

Filter

area

|

Hoses

(inner diameter, mm)

|

Motor

standard

(3ph, 2800 r/m, 50Hz, IP54)

|

Dimensions

(cm)

|

Weight

(kg)

|

|

Magnetic

drive

|

Plates

(diameter, cm)

|

Cloth

|

Cartridges

|

square

dm

|

Suction

|

Discharge

|

KW

|

Volt

|

Amp

|

L

|

W

|

H

|

Net

|

Gross

|

|

CF15

CM

|

-

|

-

|

15-10"

|

495

|

38

|

38

|

1.10

|

220/380

|

4.43/2.55

|

60

|

48

|

95

|

56

|

68

|

|

CF15

PM

|

37-29

|

-

|

-

|

220

|

38

|

38

|

1.10

|

220/380

|

4.43/2.55

|

60

|

48

|

95

|

60

|

72

|

|

CF15

BM

|

-

|

1

|

-

|

130

|

38

|

38

|

1.10

|

220/380

|

4.43/2.55

|

60

|

48

|

95

|

56

|

68

|

|

CF15

C20M

|

-

|

-

|

15-20"

|

990

|

38

|

38

|

1.10

|

220/380

|

4.43/2.55

|

60

|

48

|

120

|

62

|

74

|

|

CF15

P20M

|

70-29

|

-

|

-

|

430

|

38

|

38

|

1.10

|

220/380

|

4.43/2.55

|

60

|

48

|

120

|

68

|

80

|

|

CF15

B20M

|

-

|

1

|

-

|

230

|

38

|

38

|

1.10

|

220/380

|

4.43/2.55

|

60

|

48

|

120

|

62

|

74

|

|